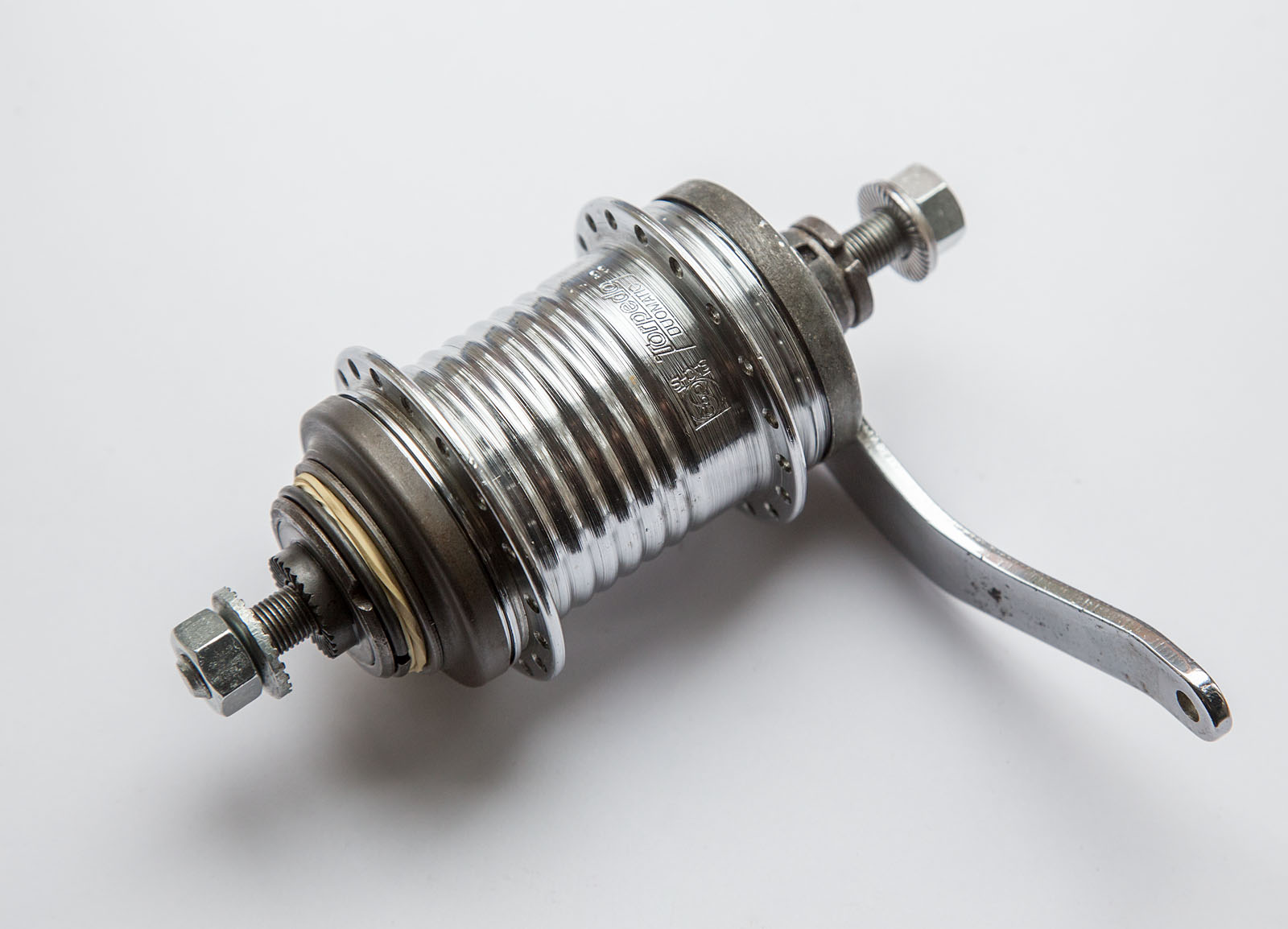

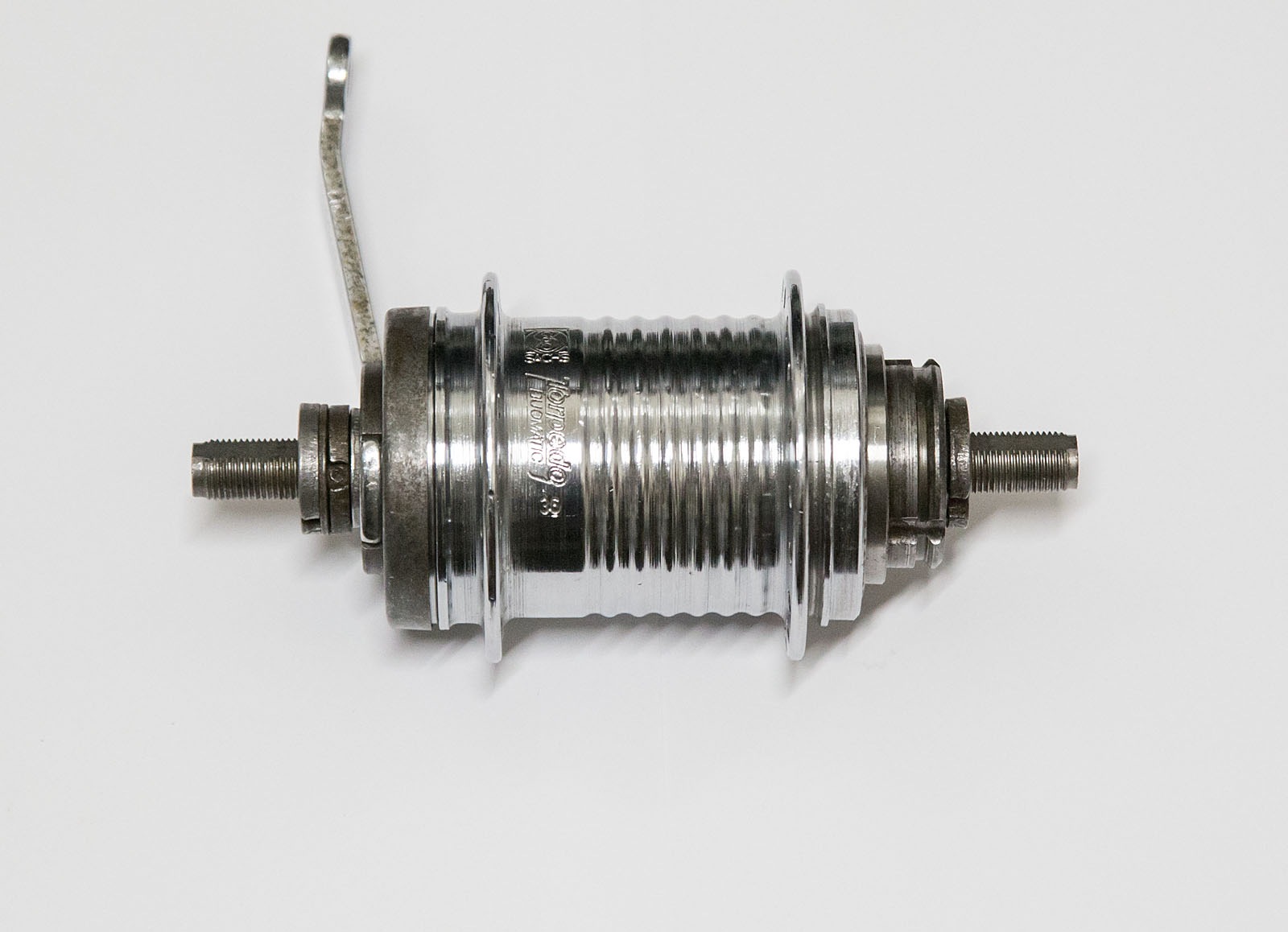

Rebuilding a Torpedo Duomatic model R2110 hub

The Fichtel & Sachs Torpedo Duomatic model R 2110 from the seventies and early eighties was the successor to the sixties era Duomatic model 102. In some ways, it was improved (a stronger dog ring, which is the weak point of the 102) but other production cost-saving changes were definite downgrades (a more wear-prone axle without anti-rotation flats and a "non-replaceable" axle cone integrated with the sun gear). However, if properly maintained and greased, it works great and will last for a long time.

See also: More photos of the R2110. For diagrams and spare parts, visit the R2110 page on scheunenfun.de.

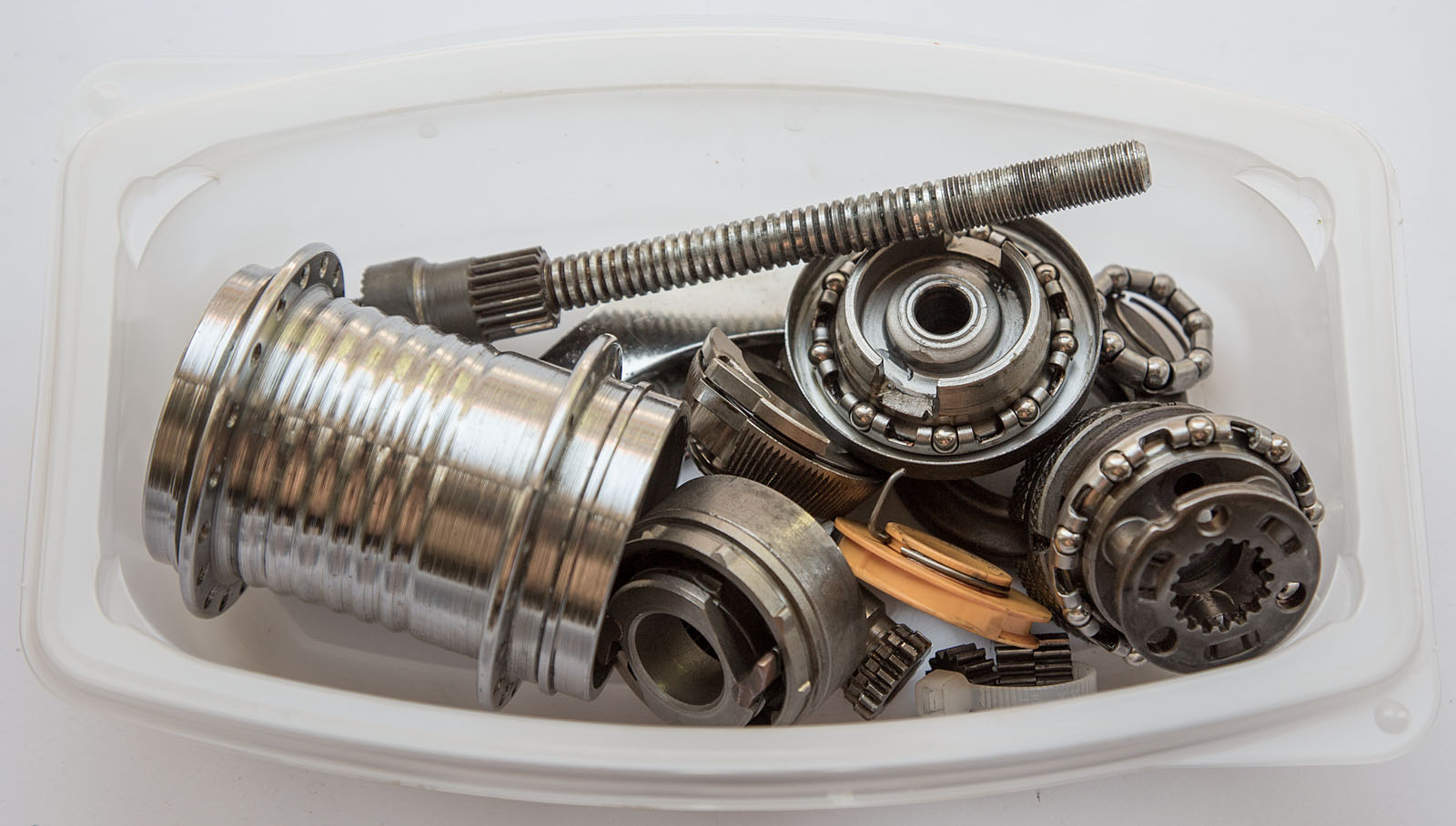

The mechanical design of the R2110 was simplified a bit compared to the 102, resulting in fewer machining and lathe operations, and one non-load bearing part in the gear shift mechanism was made of injection molded polymer/nylon instead of metal.

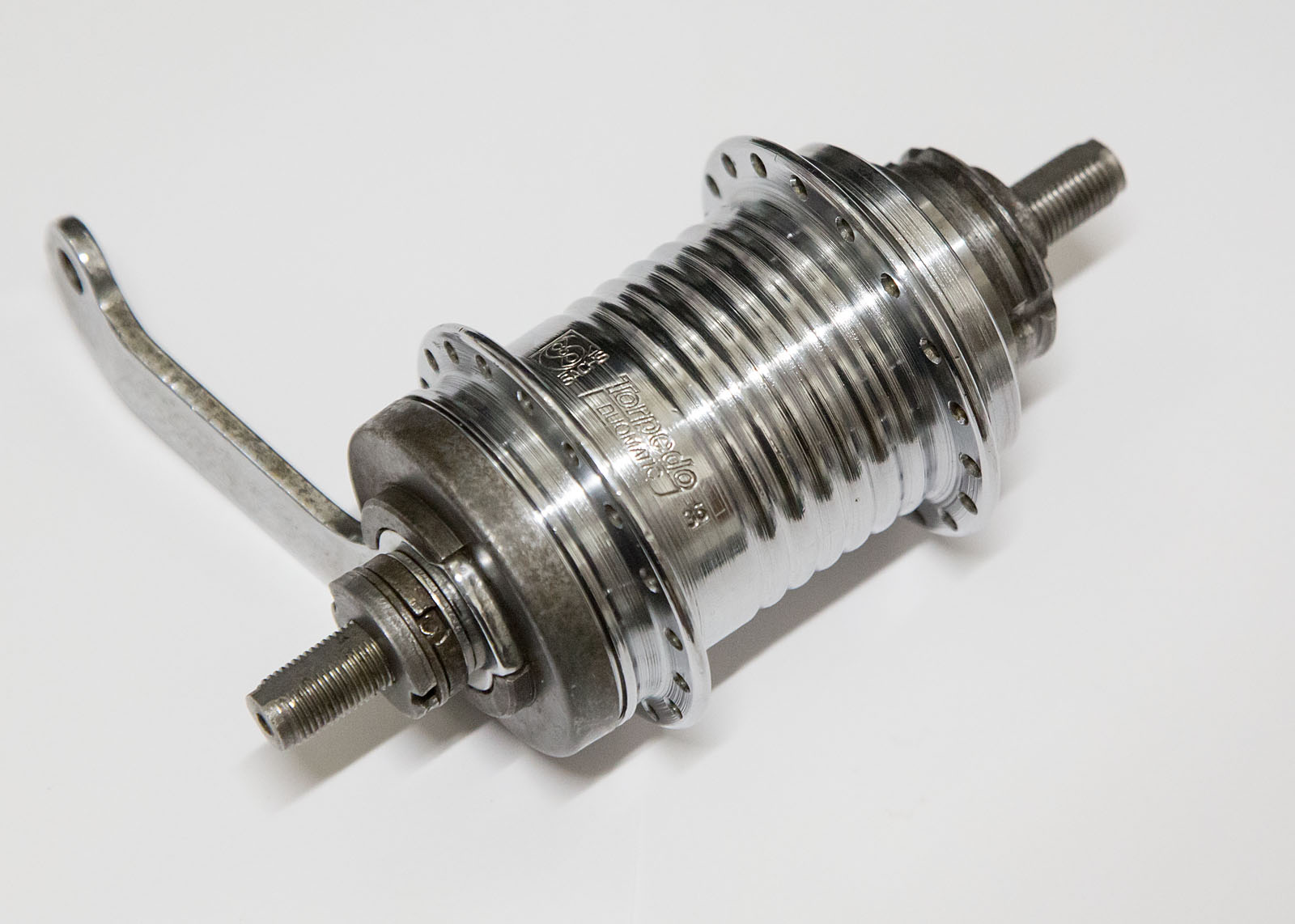

The fixed axle cone / sun gear to the right is from the factory threaded on to the axle and fixed in place with threadlocking glue. The cone must be securely tightened against the bike frame's fork ends to prevent it from rotating under use, which would damage the hub. The cone has radial serrations on its face that will bite into the frame dropouts, locking it in place.

The axle on the above photo has practically no wear, which is optimal for a rebuild but not typical of the old hubs found today ~40 years after they were produced.

An example of typical axle wear, can still be used, but additional wear will become more and more problematic:

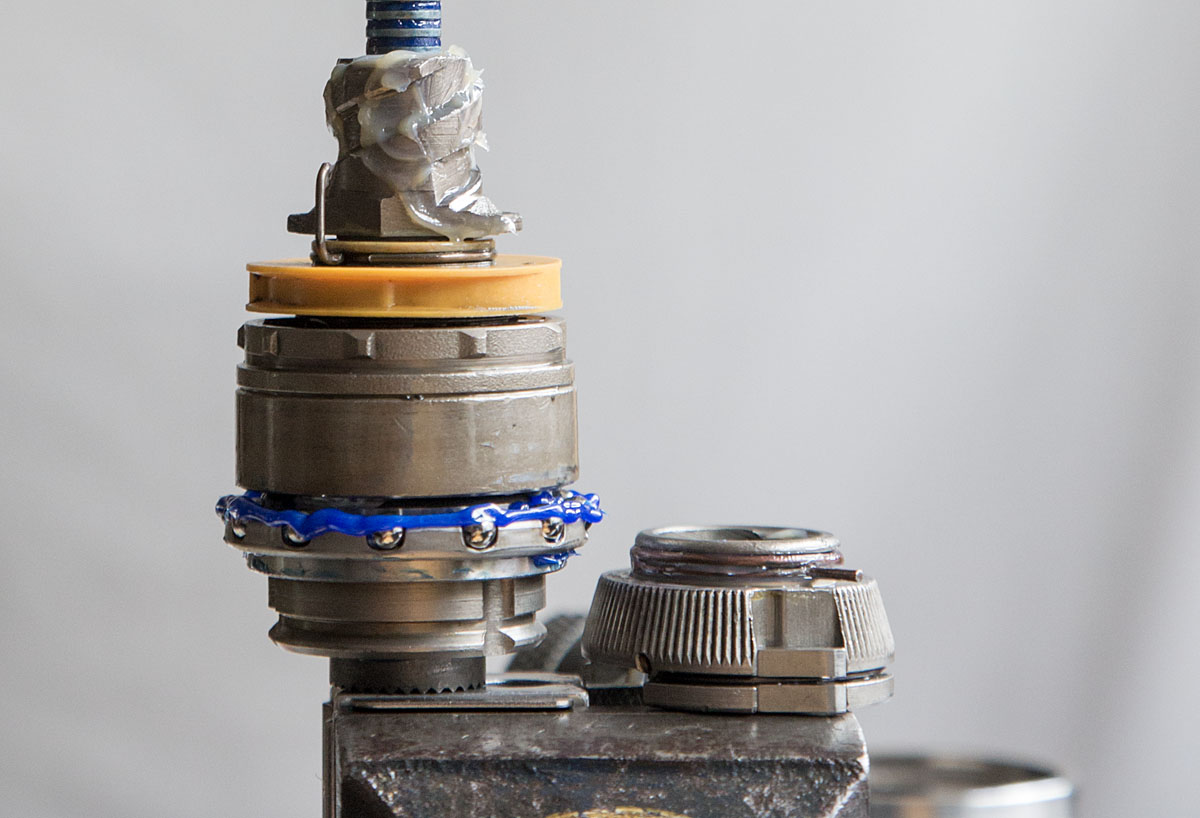

An example of a severely worn and water ingress damaged non-original axle:

It is therefore very important to apply bearing grease to the middle section of the axle. Use relatively "thick" grease like LNGI grade 2 to make sure it does not wash out. Make sure to also push it into the grooves.

Lubrication of the rest of the hub is just as the model 102, meaning oil on the pawls and ratchet teeth, grease on gears and ball bearings and special brake grease on the steel brake cylinder.

Fitting the R2110 into 120-130 mm frames

The R2110 with the long 158 mm variant of the axle can be spaced out to 120 mm by adding washers or extra nuts to only the left side of the axle (and building the wheel with a bit of "dish") because the right cone needs to be in direct contact with the frame as explained earlier.The original 112mm Over-Locknut-Distance (O.L.D.) without any additional spacers added. The left side of the axle is protruding longer than the right side:

To also use the hub in a contemporary frame with 130 mm spacing, a special anti-rotation locking spacer for the right side of the axle can be made from a damaged/discarded R2110 axle cone. It was Jens Hansen that originally got the idea.

Alternatively, an anti-rotation spacer can also be made from a part that is easier to find: A SRAM P5/S7 serrated axle cone with part number "65 0308 024 000" matches the serrations of the R2110/A2110 axle cone and can be modified to work as a locking spacer:

Spaced for 128mm:

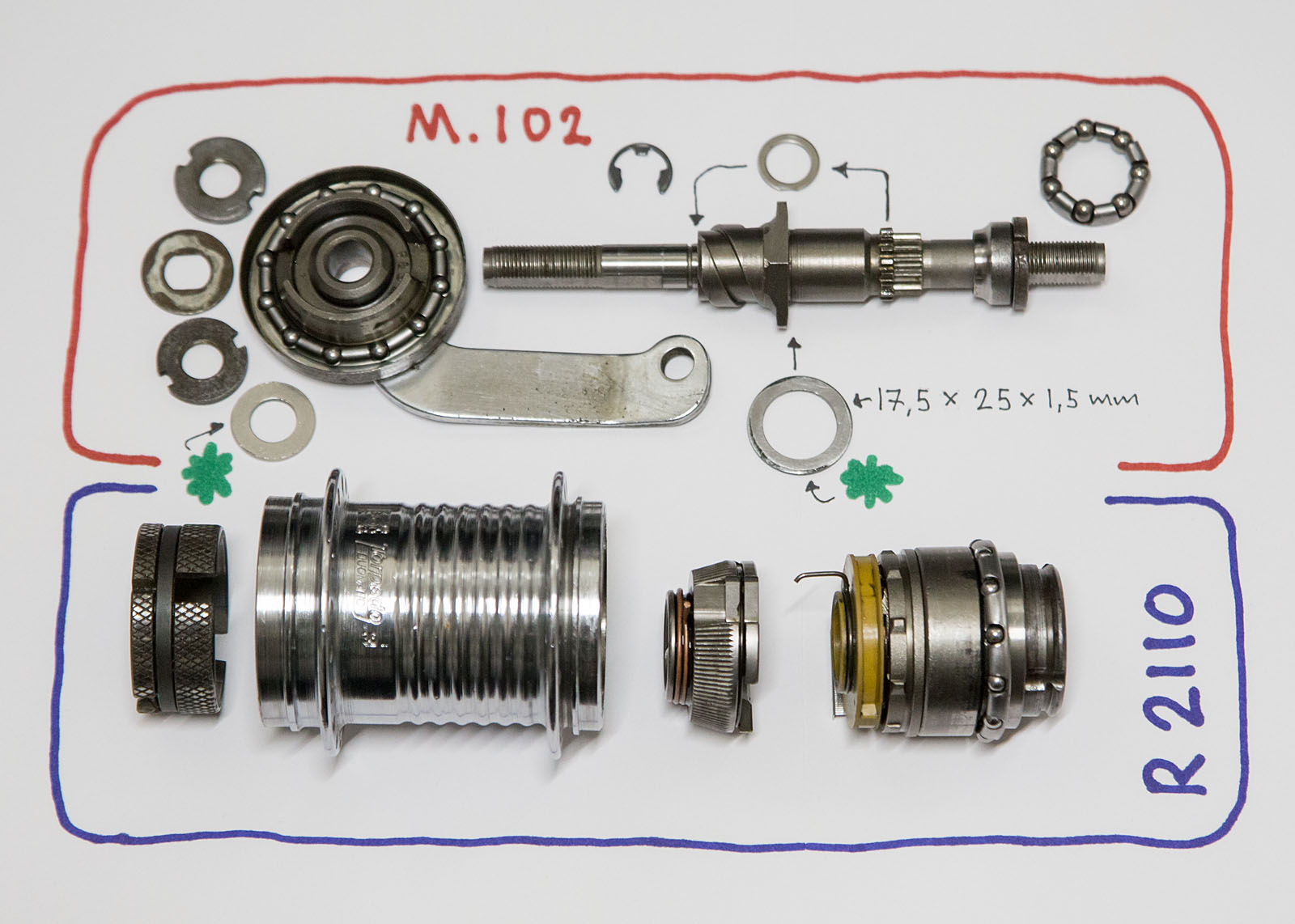

Hybrid Duomatic R2110 + 102 = "R2212"?

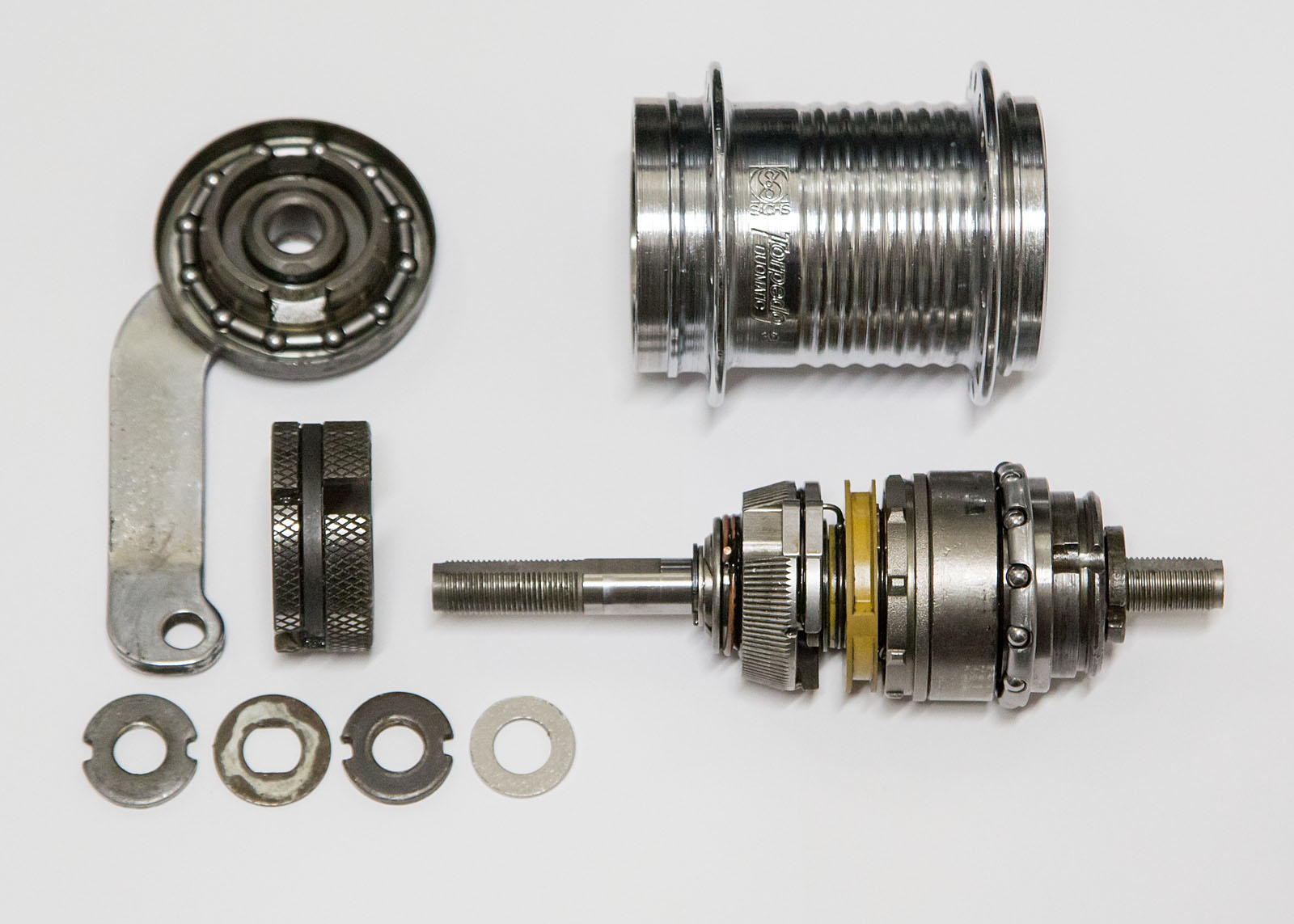

Because of the re-designed mechanics of the R2110 hub compared to the earlier model 102, only a few parts like the bearing rings, planet gears and brake cone pawls are interchangeable. But I have discovered that if the parts are mixed in a certain way with some extra washers added, a hybrid Duomatic can be assembled using the axle and associated parts from a model 102 mixed with a R2110 drive unit, in a R2110 hub shell:

This is the schematics for the parts mix. The two washers marked with a green star need to be added. The left washer is just a standard M10 washer with a 10,5 mm hole so the lock nuts do not bottom out on the end of the axle threads. The big, central washer is for stabilizing the shift plate so it cannot tilt. It is a custom size so it must be fabricated. Filing or grinding down a thin washer like that is difficult, but since it is not under great pressure during use, it can also just be cut from a piece of 1,5* mm sheet metal (aluminium should be fine) or perhaps polycarbonate. It is important that the outer diameter is not larger than 25 mm.

*Update 2024: Hub-brother Thomas has built and ridden a R2212 successfully but needed to reduce the thickness of the custom washer to around 0,8 - 1,0 mm to get the shifting to work consistently.

Note that the thrust washer needs to be moved to the other side of the snail component to provide proper clearance. If you experience that one or both of the first-to-second and second-to-first toggle shifting points are rotationally too close to the point where the hub starts to engage the brake, using a slightly worn brake cylinder might help. Also check that the friction spring on the nylon shifting plate is not loose and provides some resistance to rotation.

Another benefit of this setup, apart from using the better engineered 102 axle, is that some very commonly available Torpedo Dreigang model H3111 (AKA T3) spareparts are now compatible with the hub, as it also uses a 10,5 mm axle with flats. Meaning the fixed bearing cone (add a spacer on the outside between it and the locknut as it is a little bit shorter), left bearing cone and brake arm assemblies, plus axle nuts and standard anti-rotation washers can be used.

If you have built one yourself, please share your test results with me.

Page last updated 2024-03-22 19:23. Some rights reserved (CC by 3.0)